Description: To establish a mustard seed oil plant, the right planning and equipment are immensely important to consider. To understand the steps of how to start, read the article.

Mustard oil is a kind of edible oil with a range of nutritional attributes. It is used widely in different functions, especially in culinary purposes. Establishing a mustard oil mill plant is no more a tough job. If you are in a mustard oil mill project, you can certainly start it with a few considerations. It does not need king-sized operating machinery and equipment. Only, you need to understand the procedure thoroughly and must have good infrastructure with the right use of machines to work efficiently. Machinery placement is also easy as it doesn’t need a large space. With the right plan and equipment, it is simple to set up a mustard oil mill plant effectively.

Steps to pursue to create mustard oil mill plants:

Look For a Suitable Space

One of the key factors you should keep in mind is to choose a suitable space where the availability of raw material is easy. Also, the place should be appropriate regarding the marketing aspect. Once, the space is available, plan correctly to setup oil mill machines to start oil production. Businesses with fewer budgets can also set up a mustard oil plant as it does not need heavy machinery and tools. They can get the required equipment from recognized oil mill machinery suppliers.

Get Some Knowledge to Start This Business

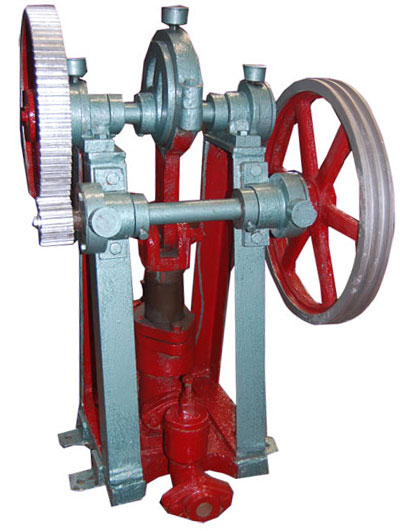

Mustard growth is plenty in several countries. The cost of raw seeds depends on its excellence and availability. With the right machines like hulling machines, flaking machines, crushing equipment, and seeds extruder, provided by oil mill machinery manufacturer, the things move on smoothly. The processing of seeds, filling or bottling, and transport are some crucial steps to follow. Once you make the plan ready, you can easily estimate the profit.

Research On Production Procedures

The grinding procedure is uncomplicated. Seeds are removed from the plants. Yellow and black seeds are thought the finest for oil processing. Sometimes, some other spices are used while extracting oil and it determines the color of the produced oil.

After selecting the seeds, the next step is to check the quality of them. Moisture test, color checking, impurity test are some examinations to determine the standard of seeds. After determining the quality, seeds are sent for cleaning to remove stone, dust, wood particles, and other foreign objects from them. Oil plant machine manufacturers supply high-quality cleaning sieve, stone remover, hulling machine, and more to do the task effectively.

For intensive cleaning, cleaned seeds are gone through hoopers. From this pace, oil procedure starts with the help of a high-quality oil extraction machine. In this stage, the oil has gone through testing for detecting moisture, warmth, and density and sent to the next level.

In the filtration and refinery section, all impurities are eliminated and the oil is sent for the quality testing. Equipment provided by oil plant machine manufacturers checks the odor level, acid content, chemical content, and other things to make the oil edible and healthy.

Refilling, Marketing, And Distribution Of Processed Oil

With the best quality oil filling machines, supplied by oil mill machinery suppliers, the stock has bottled or refilled and distributed to different stores.

For running an oil mill plant successfully, machines and equipment should be the best in quality that these can help in bulk production. A certified and experienced oil mill machinery manufacturer creates top-notch machinery and tools to support oil mill industries. Punjab Engineering Works is one of the leading oil plant machine manufacturers where mill owners have top-quality oil extraction machine and other equipment to support oil mill industries.

Copyrights 2020 .Powered by Onqanet.com