Oil extraction is the method behind the production of useful commodities made from agricultural products, such as peanut butter, coconut oil, and scented soaps. Production of these items requires an oil extraction machine. Oil extraction machinery enables agricultural firms to increase production. Based on a screw mechanism, these oil expeller pressers use heat, friction, and pressure to squeeze oil out of various materials.

In this Article Operation, Application and Composition of oil extraction machinery

What Is an Oil Extraction Machine?

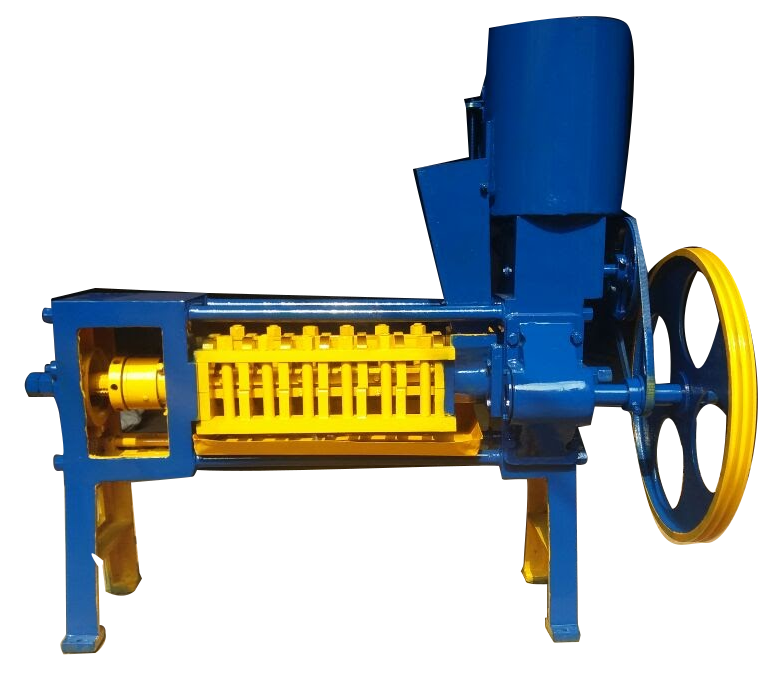

An oil extraction machine, often known as an oil press or expeller, requires higher pressure and heat to “squeeze” the oil from raw material. These goods, which include seeds, nuts, fruits, vegetables, and leafy plants, release their oils, without the use of chemicals.

An oil machine uses a screw press. To feed nuts through the screw press, for instance, peeled or sealed groundnuts. The heavier nut from the lighter shells gets separated during the peeling process using strong centrifugal forces or fan airflow.

The product is then moved to the screw system, which consists of a screw inside a high-pressure cylindrical chamber after it is peeled. As the material gets screwed through, which generates heat and friction.

Besides to the heat, high pressure also squeezes out a lot of oil. Some of the product’s proteins may be denatured, and the oil’s viscosity increases gradually for better movement.

To remove any fibres or particles from the oil as it gets pumped out, it must pass through a screen or filter. Which makes it smooth and clean. The oil pours out into another container as the machine’s leftover squeezed seeds solidify into a cake that gets removed.

Uses of Oil extraction machine :

oil mill machinery is versatile. Different models help produce various agricultural products and the oils are the primary product for a wide range of products, including cooking oils, fragrances, cosmetics, soaps, pet food, biofuel, wood treatments, and paint.

The byproducts of the extraction process can be valuable materials as well. After the extraction of oil from the seeds, the residual is a canola meal, which contains 38–42% protein. It is a well-liked ingredient for animal feed because it has a good balance of amino acids. Oil mill machinery can aid in the diversification of a single commodity.

Oil products are an excellent approach to increasing the value of crops due to their price. Many oils have suffered large price rises, particularly those that make biofuels.

Parts of an Oil extraction machine:

Oil Extraction Machine Components

Although oil extraction machines are customisable in a variety of ways, the following are some of the most common parts:

Oil extraction is a smart choice if you’re searching for another use for a crop. You can generate new sources of income or get rid of surplus inventories.

Copyrights 2020 .Powered by Onqanet.com